NIS-AX Motion Sensor

Contents

- 1 General information

- 2 Mechanics

- 3 Accelerometer sensor properties

1 General information

1.1 Overview

- LoRa™ WAN 1.0.2 EU Class A & C

- Activation by Personalization (ABP)

- Over-The-Air Activation (OTAA)

- SIGFOX™ ready

- Fully certified on major LoraWan & Sigfox networks

- Easy to use and deploy

- 3.6V / 2200mAh Primary battery Li-SOCl2 embedded

- Magnetic switch and LED to ease the installation

- RoHS conform / Pre-Certified ETSI EN 300-220 / RED compliance under certification

1.1.1 RF Performance

- TX Power 14 dBm (25 mW)

- RX Sensitivity -137 dBm

- Approx. 10 km range

- Integrated PCB antenna

1.1.2 Environment

- Operating temperature -40°C to +85°C

- Storage temperature 30°C recommended (to limit battery self-discharge)

- Rel. humidity 0% to 95% (not condensing)

1.1.3 Options

- External antenna

- SDK for your SW development purposes

- 10-30V external power supply

- Compatible with the NEMEUS PicoGateway for private networks

1.2 Installation

By using the internal antenna, the position of the sensor is critical.

Install your product as high as possible, and prefer unobstructed area (concrete and metal are the worst materials).

If you cannot fulfill these conditions, it is still possible to use an optional external antenna.

2 Mechanics

- Dimensions 60 x 95 x 85mm (109mm including fixing brackets)

- 96mm spacing between brackets

- IP 65

- Solid ABS & PC material

3 Accelerometer sensor properties

This sensor has full scales of ±2g/±4g/±8g/±16g and is capable of measuring accelerations with output data rates from 1 Hz to 5.3 kHz.

- Impact detection

- Tilt measurement

- 3D orientation measurement

- Activity and inactivity duration measurement

- vibration monitoring system

This sensor can check the vibrational footprint and thus the health status of your machine several times a day and provide data to the server. This system makes it possible to carry out maintenance based on reliability by anticipating problems. This system also allows daily measurements to be made on machines in dangerous, remote and inaccessible locations. It can detect whether the machine is running or not.

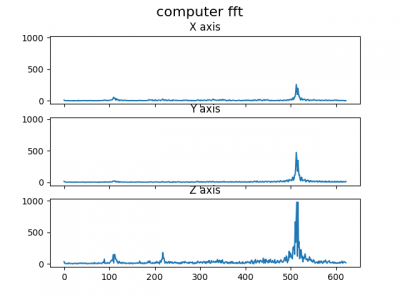

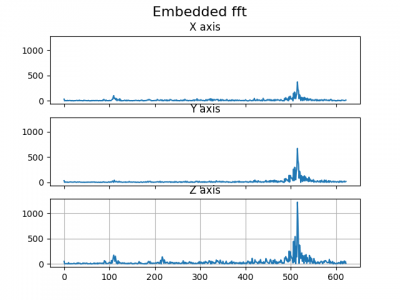

3.1 Frequency response (mg/Hz)

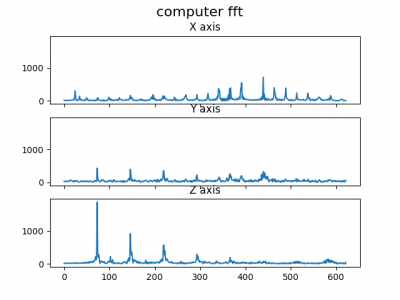

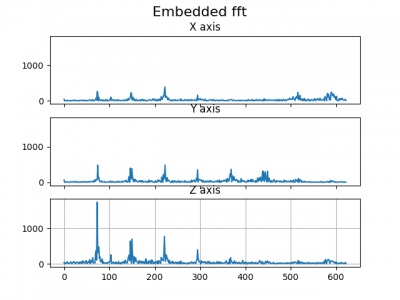

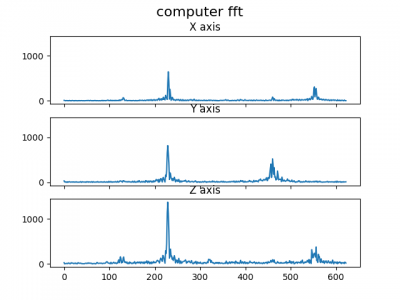

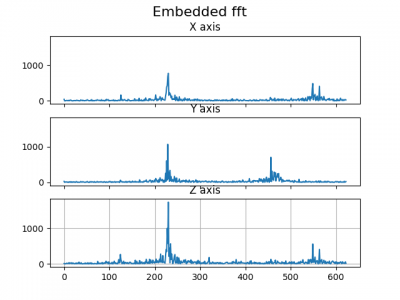

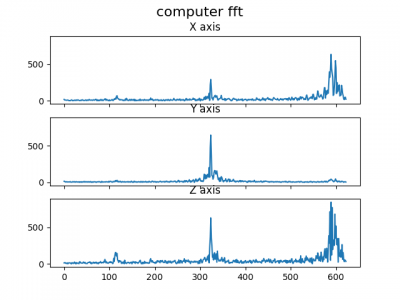

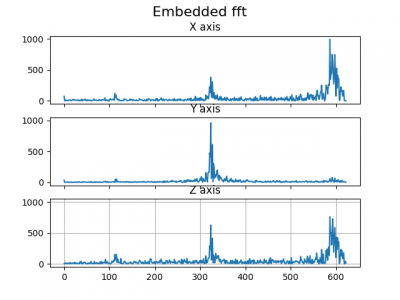

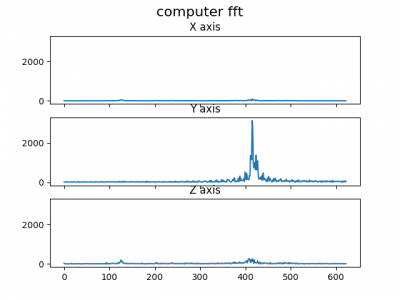

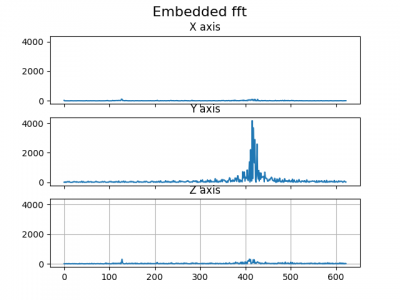

3.2 = Comparison for 80Hz vibration

3.3 = Comparison for 230Hz vibration

3.4 = Comparison for 330Hz vibration

3.5 = Comparison for 430Hz vibration

3.6 = Comparison for 530Hz vibration

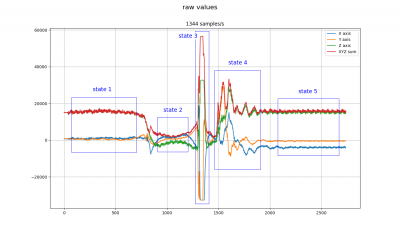

3.7 Freefall tests

To test human fall, we made tests at 1344Hz. These tests were carried out from a height of 75 cm, representing a worse case, where the fall is from a very low height.

3.7.1 state 1

Initial state, in the case shown, gravity appears on the Z axis, the sensor being positioned horizontally.

3.7.2 state 2

Free fall, we get an acceleration that decreases for a short moment. That's the condition we can detect. The vectorial sum of the 3 axes tends towards 0G.

3.7.3 state 3

Impact. For the test carried out, the impact took place on a flexible surface (foam). Nevertheless, we can measure a large shock. The idea is to detect this activity following the detection of free fall.

3.7.4 state 4

bouncing. Following the impact, a few jolts may appear, depending on the environment in which the fall occurs.

3.7.5 state 5

After a fall, the human body may not move for some time. The vector sum always corresponds to gravity, however the sensor may have changed its orientation.